Mokveld's Total Velocity Management® concept: intelligent valve design that carefully manages fluid velocity in all areas of the valve, leading to increased reliability and reduced operational costs

Local high fluid velocities due to preferential flow paths are the prime source of noise, erosion, vibration and malfunction resulting from unbalanced forces. Prevention is better than cure. Mokveld Total Velocity Management® concept is an intelligent valve design that carefully manages fluid velocity in all areas of the valve (trim and body) by smart engineering of the relevant valve parts. Source treatment by Total Velocity Management® is the key to reliability.

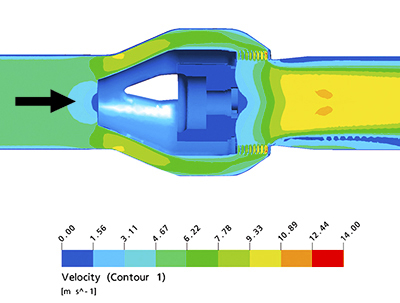

In the Mokveld axial flow design the streamlined annular flow path - and the evenly distributed flow through the cage - reduce high local velocities, turbulence and impacts of flow jets and particles. This is fundamental for reliable valve performance because vibration, erosion and unbalanced flow and forces are avoided.

With a minimum of turbulence and change of the fluid velocity, there is no energy conversion in the valve body itself. Pressure drop is taken over the trim only, which has been specifically designed for this task. For extremely severe conditions the valve is often used as axial choke valve with - for instance - Tungsten Carbide material used for cage and piston.

Axial flow and source treatment by Total Velocity Management are the key to reliability.

Read more about Mokveld TVM axial control and axial choke valves.

The basic rules to minimize erosion in valves are:

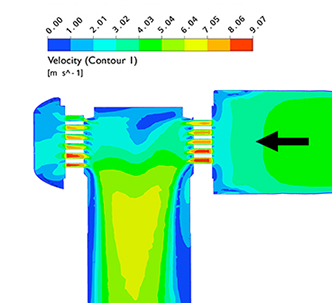

Although any angle type choke valve is inherently more susceptible to erosion than an axial type, Mokveld has redesigned the entire flow path to minimize this adverse effect. Clever engineering of the flow and velocity patterns in the gallery, trim and outlet area can reduce erosion significantly. As a result of many years of research, testing and 3D CFD studies, we managed to eliminate turbulent flow in the gallery area, evenly distribute the flow through the cage (full surround flow path) and to reduce velocity through the bean. This ensures reliable valve performance as vibration and unbalanced forces are avoided and erosion is reduced by a factor 4.

With a minimum of turbulence and change in the fluid velocity, the energy conversion in the valve body itself is limited. The pressure drop is mainly over the trim, which has been specifically designed to withstand high erosional velocities. Our standard design includes a cage, piston and bean of solid high-quality Tungsten Carbide with the grade selected depending on the service.

The angled shape of a choke valve implies a change in flow direction. TVM eliminates erosion damage caused by preferential flow.

Read more about the Mokveld TVM Angle choke valves

If you would like to know more about Mokveld's TVM, please don't hesitate to contact us. We are glad to explain you everything about how Mokveld's Total Velocity Management concept can help you achieve increased reliability and reduced operational costs.